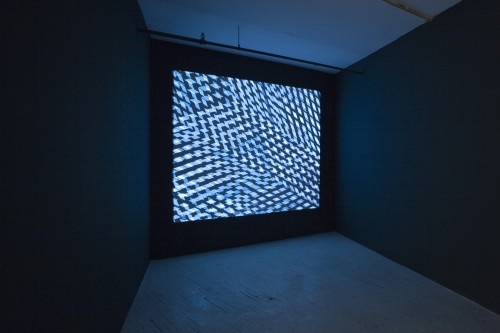

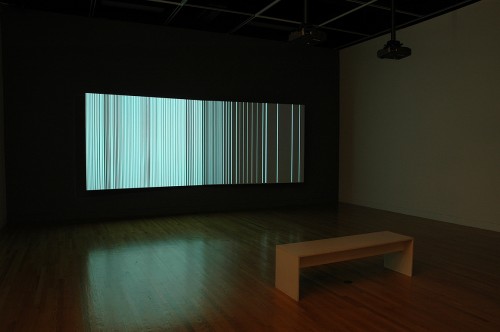

Modern Societies

2021

Texas State Galleries (Jan. 19–April 11, 2021)

Single-channel video installation

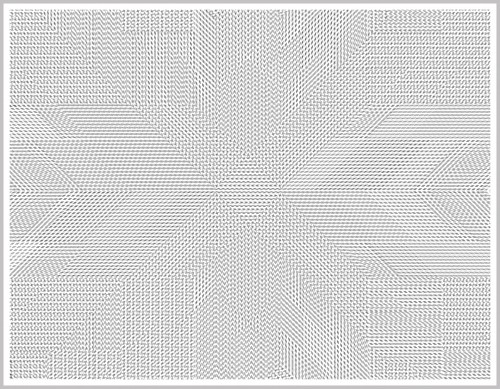

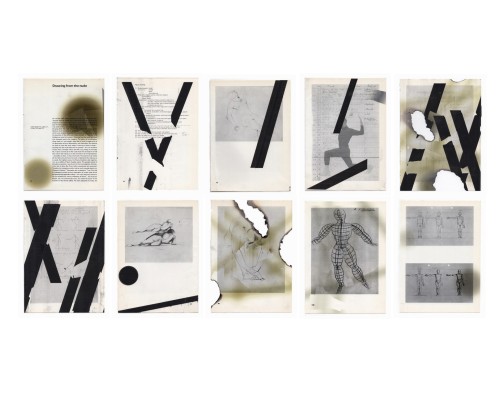

Der Mensch

2020

Der Mensch/ Man, Gallery 103, University of Tennessee Knoxville, (Jan. 27-Feb. 21, 2020).

Pigment prints

Sargassum Summer

2019

St. Philip, Barbados

Video, Single channel projection. Color. Sound. 8:40 min. 2019

New Brutalism

2010

Radiator Gallery, Long Island, NY;

Camera Club of New York, New York, NY;

Angell Gallery, Toronto, ON

Chromogenic prints

Second Skin

2006

Galerie Thérèse Dion, Montréal, QC; FOFA Gallery, Concordia University, Montréal, QC

Chromogenic print

The White Maze

2005

Harvard Graduate School of Design, Cambridge, MA;

Galerie Thérèse Dion, Montréal, QC; Private collection

Photographic Installation, Chromogenic print, Models

Equivalents (Parallel Lines)

2007

Leonard and Bina Ellen Gallery, Montreal, QC; Elektra Festival International Arts Numériques, Montreal, QC

Two-channel video installation

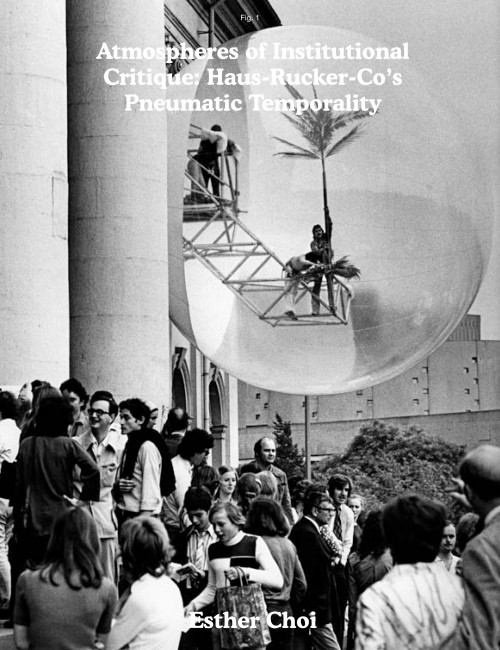

Atmospheres of Institutional Critique: Haus-Rucker-Co's Pneumatic Temporality

2015

Hippie Modernism: The Struggle for Utopia. Edited by Andrew Blauvelt

6449 words

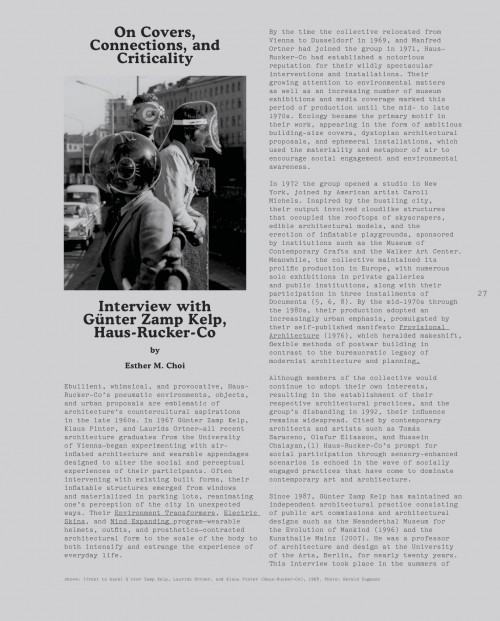

On Covers, Connections, and Criticality: Interview with Günter Zamp Kelp of Haus-Rucker-Co, 2015

2015

Hippie Modernism: The Struggle for Utopia. Edited by Andrew Blauvelt.

Günter Zamp Kelp

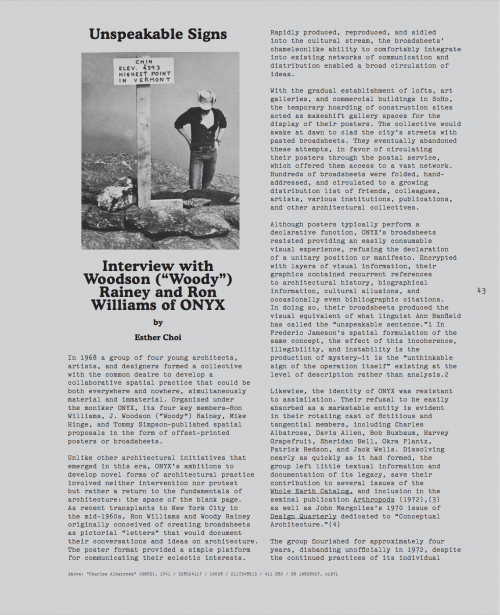

Unspeakable Signs: An Interview with ONYX

2015

Hippie Modernism: The Struggle for Utopia

Woodson Rainey, Ron Williams

Natural Disasters: On Young and Giroux’s Infrastructure Canada

2015

Into the Wild. Edited by Caitlin Sutherland

699 words